The packaging of products has over the last number of years undergone an evolution.

Innovation in packaging design, size and materials has had a massive impact on retailers everywhere. And this is because the synergy between the packaging itself and the marketing messages being communicated through it has never been more effective – or more loud.

So much so in fact that brands are continuously looking at ways of converting packaging interest into actual sales by making the packaging an extension of the product itself.

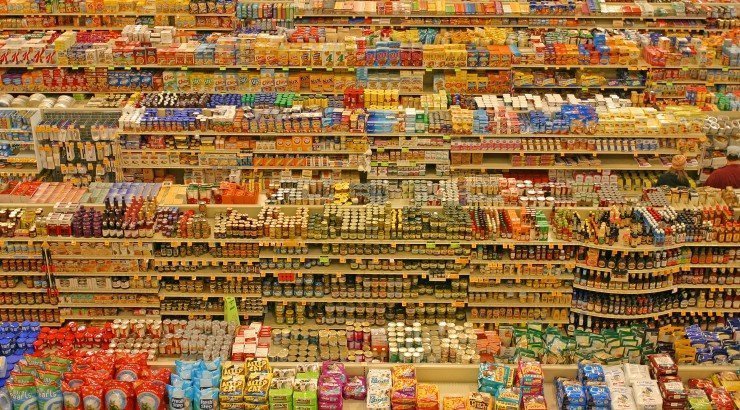

Never before has packaging been more in your face.

Walking into a store today, one cannot help but feel almost overwhelmed by the sheer volume of brands on the shelves. And never have consumers been so unwittingly influenced into buying a product based on its packaging.

New products are being purchased at record levels by the mere impact that packaging is having on the psychology of a consumer’s decision making process when buying something.

But with brands investing so heavily in the packaging of their products, what are the environmental repercussions?

Consumers globally are becoming more conscious about the impact that their actions are having on the planet and this includes the rubbish they discard.

As a result, whilst most packaging materials today still include tin, glass, hard plastics, plastic films, oils, chipboard and others, there are an increasing number of manufacturers who are striving to find ways to produce renewable and biodegradable packaging.

Further, much is being done to increase environmental awareness on an international scale and this green movement is seeing more companies turn to sustainable or environmentally friendly packaging for their products.

What type of packaging materials actually cause less damage to the environment?

Aside from renewable and recyclable packaging materials, manufacturers are also making use of biodegradable packaging that breaks down easily in soil or the atmosphere.

One such biodegradable material that is becoming increasingly popular is bagasse, a fibrous matter that remains after sugarcane or sorghum stalks are crushed to extract their juice (Wikipedia).

Bagasse products are said to be fully compostable and take between 60-90 days to turn into compost in commercial composting conditions.

What products can be manufactured using bagasse?

A range of products in fact from paper bags, to plates, to-go (takeaway) boxes, cups, bowls and even wooden type products, likes tables, walls and chairs.

At Dynamec, we strive to deliver packaging solutions that don’t only meet the demands of our clients but that also reduce the impact of our ecological footprint. Visit our product catalogue to see our range of eco-friendly products.